Smart active temperature control in satellites

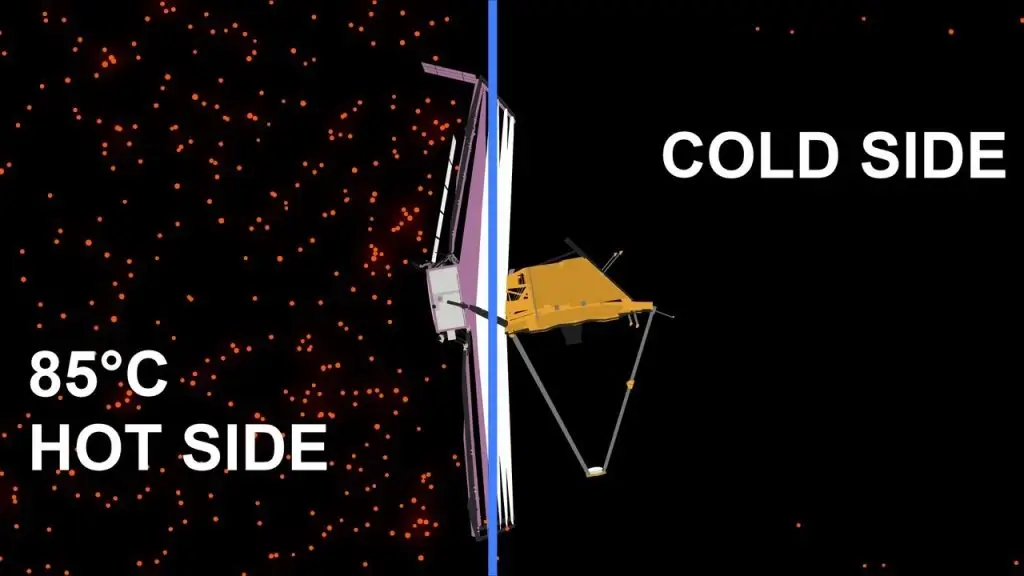

Maintaining precise thermal control in satellites is a critical requirement for mission success. The harsh space environment, characterized by extreme temperature swings, vacuum conditions, and variable solar radiation, can severely impact satellite components. Sensitive instruments, such as optical cameras, detectors, or scientific payloads, are particularly vulnerable to temperature fluctuations, which can degrade performance or even cause permanent damage.

Thermal Challenges in Space

Satellites experience highly dynamic thermal environments:

- Sun and shadow transitions: Low Earth Orbit (LEO) satellites can pass from sunlight to Earth’s shadow multiple times per orbit, leading to rapid temperature changes.

- Radiative cooling: In the vacuum of space, heat dissipation occurs primarily through radiation rather than convection, making thermal control more complex.

- Internal heat generation: Electronics and payload instruments generate heat, which can create hotspots if not properly managed.

To address these challenges, satellites rely on Thermal Control Units to actively regulate temperatures, ensuring all subsystems remain within operational limits.

Active Thermal Control with TCU1

Thermal Control Unit is designed for small and medium satellites. It has a smaller version with half size & dimensions & limited number of I/Os TCU-L for smaller projects. TCU integrates high-precision thermal monitoring and direct heating control to maintain the stability of critical payloads.

Key features include:

- Multi-sensor integration: Supports over 110 temperature sensors distributed across the satellite structure and payload.

- Direct heater control: Drives up to 48 independent heater channels to actively manage local temperatures.

- FPGA-based architecture: Built on Microchip SmartFusion2 FPGA, offering deterministic, radiation-tolerant control.

- Modular hardware design: Two separate boards integrated in a single enclosure for reliability and ease of maintenance.

By continuously monitoring the thermal state of the satellite, TCU1 can dynamically adjust heating to prevent temperature excursions beyond allowable limits, protecting sensitive instruments from thermal stress.

Case Study: Maintaining Temperature of a Sensitive Camera on a 250 kg Small Earth Observation Satellite

Satellite and Payload Overview

- Satellite mass: 250 kg

- Payload: High-resolution optical camera for Earth observation

- Thermal sensitivity: Operational range 0°C to 40°C; optimal performance at 20–25°C

Thermal Challenge

The camera’s performance depends on stable temperature to avoid image distortion caused by thermal expansion of optical elements. During LEO operation:

- Sunlit periods can raise the camera temperature above 40°C.

- Shadow periods can drop temperatures below 0°C.

Thermal Control Implementation

TCU1 was integrated into the satellite’s avionics architecture to control the camera temperature. Implementation included:

- Sensor placement: Multiple sensors positioned around the camera housing and optical components to monitor real-time temperature gradients.

- Heater configuration: Three independent heater channels applied directly to the camera mount, controlled individually for uniform heating.

- Thermal control algorithm: FPGA-based control logic-maintained temperatures within the 20–25°C range using predictive and feedback-based heater modulation.

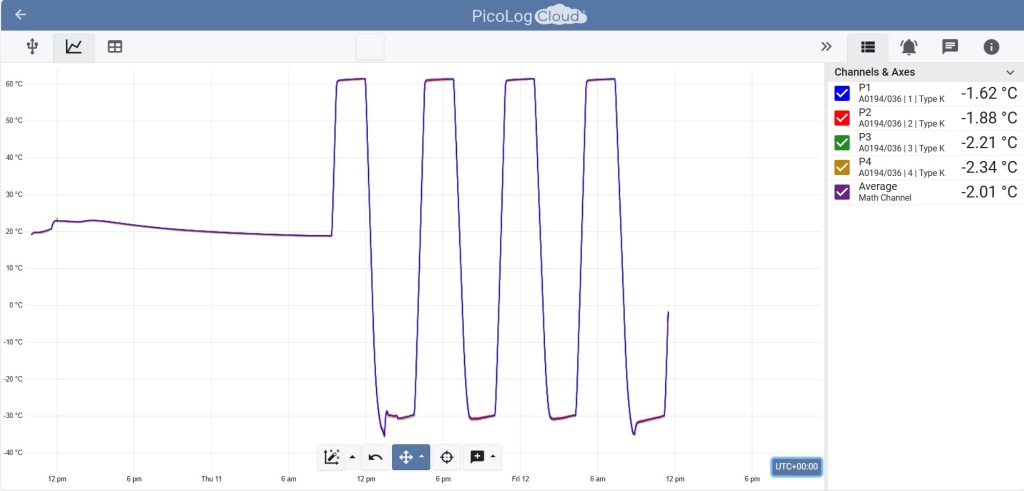

Simulation and on-orbit tests demonstrated:

- Stable temperature control: Camera temperature deviations limited to ±1°C during orbital day/night cycles.

- Improved image quality: Reduced thermal-induced distortions enhanced payload data accuracy.

- Efficient power usage: Heaters operated only when required, reducing satellite power consumption.

Results was verified in Thermal vacuum chamber. Onboard temp sensors never crossed zero during the tests.

Camera Payload Thermal Zones

A satellite camera payload has multiple components with different thermal sensitivities. Dividing it into thermal zones allows precise control using a TCU. Typical zones include:

- Optical Lens Assembly (High Sensitivity Zone)

- Components: Lenses, filters, optical mounts

- Thermal sensitivity: Very high — even small temperature changes can distort images due to thermal expansion

- Control strategy: Maintain within ±1–2 °C of nominal operating temperature (e.g., 20–25 °C)

- Heaters: Dedicated localized heaters or flexible thermal straps

- Sensors: 2–4 high-accuracy temperature sensors embedded near lenses

- Detector / Sensor Array Zone

- Components: CCD or CMOS sensor, readout electronics

- Thermal sensitivity: High — temperature affects noise levels and signal-to-noise ratio

- Control strategy: Maintain stable temperature; may require active cooling if electronics generate heat

- Heaters/Coolers: Heaters to prevent overcooling; thermal straps for heat dissipation

- Electronics and Control Boards

- Components: FPGA boards, power regulators, memory modules

- Thermal sensitivity: Moderate — most electronics can tolerate wider temperature ranges (e.g., 0–50 °C)

- Control strategy: Prevent overheating; avoid cold-induced performance drops

- Sensors: Temperature sensors near heat-generating chips

- Heaters: Only used when satellite is in shadow to avoid electronics cold-start issues

- Camera Housing / Mechanical Structure

- Components: Mounting frame, enclosure walls

- Thermal sensitivity: Low to moderate

- Control strategy: Stabilize the overall camera body to reduce thermal gradients that can stress optical alignment

- Heaters: Blanket or panel heaters on mounting points

- Sensors: Several along structural walls to monitor gradients

- Thermal Interface Zones

- Components: Interfaces between camera and satellite bus, radiators, or thermal straps

- Thermal sensitivity: Indirectly affects optics

- Control strategy: Ensure smooth heat flow to avoid hotspots or cold spots

TCU1 enables precise thermal management for sensitive payloads, ensuring instrument performance, reliability, and mission success. In small satellites, where space and power are limited, TCU1 provides an efficient, modular, and robust solution to maintain thermal stability under harsh space conditions.