Manufacturing Tolerance in Space Optics Design

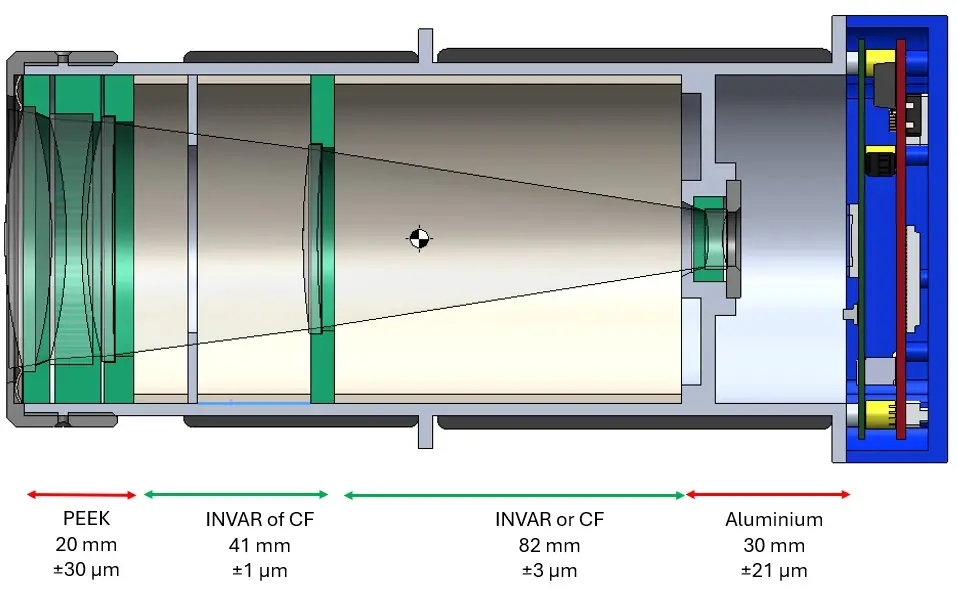

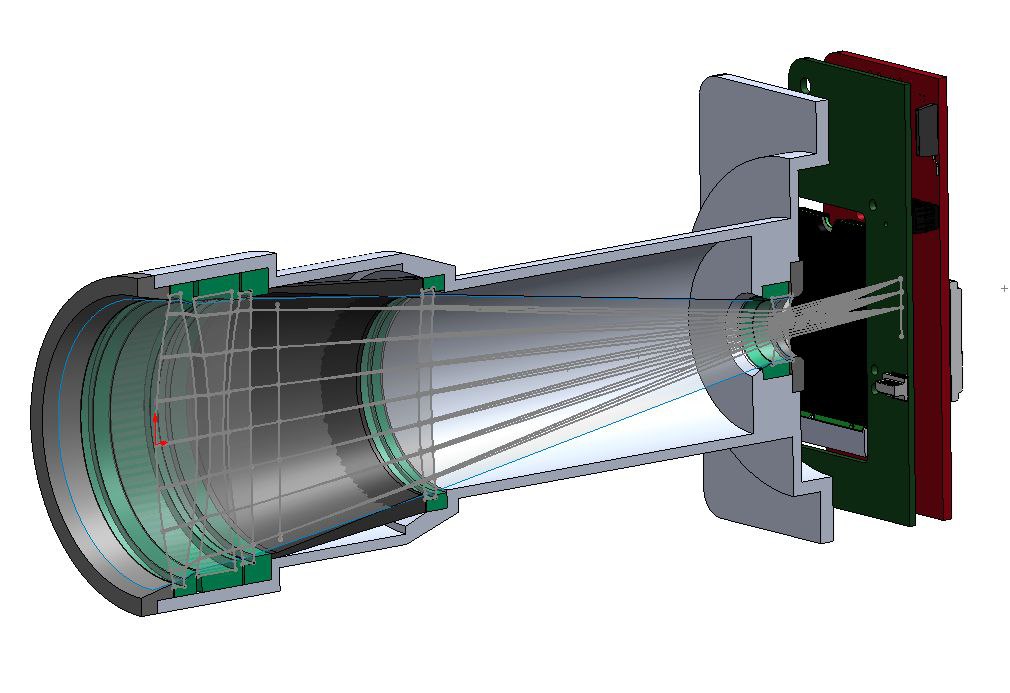

Designing optical systems for space is fundamentally different from designing for terrestrial environments. In orbit and during launch, optical payloads are exposed to extreme and rapidly changing temperatures, commonly ranging from –60 °C to +80 °C or beyond. Within this range, even micron-level mechanical changes can significantly degrade image quality.

For this reason, thermal calculation and thermo-mechanical analysis are critical steps in high-performance optical system design.

Thermal Expansion and Optical Element Displacement

All materials expand and contract with temperature. In a space optical system, this affects:

- Lens spacing

- Focal plane position

- Optical axis alignment

- Detector-to-lens distance

Even small coefficients of thermal expansion can lead to axial and lateral displacement of optical elements as temperatures change.

For example:

- Axial movement shifts the focal plane, causing defocus and loss of modulation transfer function.

- Lateral movement introduces decentring and tilt, resulting in astigmatism, coma, and image blur.

At high resolutions, displacements of only a few micrometres can reduce effective ground sampling distance and compromise mission data quality.

Impact on Image Resolution and Stability

Optical resolution depends on precise alignment between:

- The lens group

- The optical housing

- The image sensor

Thermal-induced distortion or displacement directly affects:

- Spot size and encircled energy

- MTF across the field of view

- Pixel-level sharpness

- Radiometric accuracy for scientific imaging

Without proper thermal design, a system that performs perfectly in laboratory conditions may experience:

- Progressive defocus during orbital day/night cycles

- Image distortion during high-power operation

- Inconsistent calibration over mission lifetime

Why Thermal Calculation Is Essential

Accurate thermal modelling allows engineers to:

- Predict dimensional changes across the full temperature range

- Select materials with compatible CTE values

- Design passive compensation mechanisms

- Define focus margins and tolerance budgets

- Validate performance through worst-case thermal scenarios

This analysis is typically coupled with:

- Finite Element Analysis

- Optical ray-tracing with thermo-elastic deformation inputs

- Thermal vacuum testing correlation

By integrating thermal modelling with mechanical and optical design, it becomes possible to:

- Maintain focus across the full operational temperature range

- Preserve high spatial resolution and contrast

- Ensure repeatable imaging performance over long mission durations

- Reduce reliance on power-hungry active refocusing mechanisms

In space imaging systems, thermal behaviour is not a secondary consideration—it is a primary design driver. With operating temperatures spanning –60 °C to +80 °C, precise thermal calculation is essential to control optical element displacement and preserve image resolution.

A camera’s true performance is therefore defined not only by its sensor or optics, but by how well it maintains alignment and focus across extreme thermal conditions.