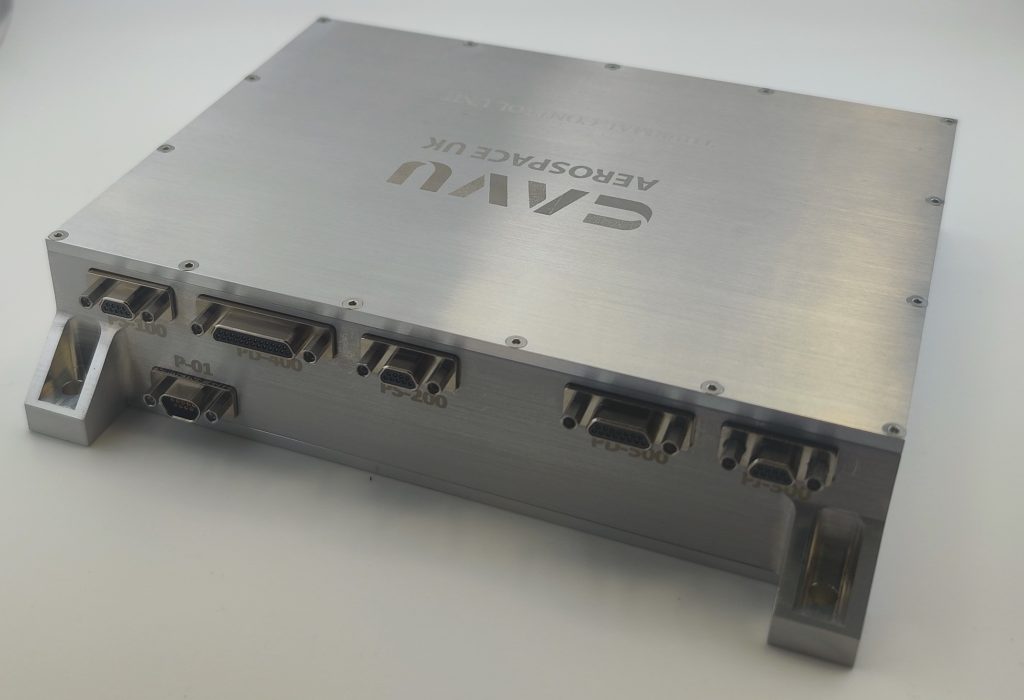

Instrument Control Unit, Integrated Subsystem for Spaceborne Applications

- February 4, 2026

- CAVU Aerospace UK

Instrument Control Unit (ICU) is redefining how spacecraft manage payload operations and thermal regulation within a single avionics architecture. Instrument Control Unit (ICU) represents a new paradigm in spacecraft instrument electronics, combining the capabilities of both a Thermal Control Unit and a Payload Interface Unit into a high-performance, radiation-tolerant subsystem based on the Microchip PolarFire FPGA SoC. This strategic integration offers significant advantages in system performance, reliability, power efficiency, and lifecycle cost for satellite and spacecraft integrators.

At its core, the ICU unifies two functions that have traditionally been implemented as independent units: the Thermal Control Unit (TCU), which manages and regulates temperatures across critical payload components and spacecraft structures through sensor monitoring, heater driving, and closed-loop algorithms; and the Payload Interface Unit, responsible for digital and analog interfacing between the spacecraft bus and onboard instruments, including command and data handling, protocol conversion, buffering, and health/status telemetry. In this article, we explore how this unified architecture enables higher performance, reduced SWaP, and improved mission reliability for modern spaceborne platforms.

Why Instrument Control Unit Integration Matters?

System integration around the Instrument Control Unit (ICU) has become a key factor in achieving higher performance, improved reliability, and sustainable mission design in modern spacecraft. By consolidating thermal regulation and payload interfacing within a unified subsystem, engineers can reduce interfaces, simplify architectures, and optimize spacecraft resources. In the following sections, we will break down the benefits of the ICU one by one, including SWaP reduction, performance gains, lifecycle efficiencies, and radiation resilience.

1- Reduced Mass, Volume & Power (SWaP) with the Instrument Control Unit

Space missions are fundamentally constrained by Size, Weight, and Power (SWaP). By integrating thermal control and payload interfacing within the Instrument Control Unit (ICU), two traditionally independent subsystems are consolidated into a single architecture.

- Mass savings: Fewer enclosures, harnesses, connectors, and mounting hardware.

- Volume optimization: Reduced board count and more efficient packaging.

- Lower power draw: Shared power conversion and regulation eliminate redundant supplies while reducing both quiescent and operational consumption.

For spacecraft integrators, this consolidation translates directly into higher payload capacity or the ability to use smaller satellite platforms, which is a major advantage for small and medium buses.

2- Enhanced Reliability Through Instrument Control Unit Integration

Fewer discrete units mean a more dependable system architecture for the Instrument Control Unit (ICU):

- Reduced component count: Less opportunity for failure in connectors, harnesses, and conversion stages.

- Single firmware domain: Eliminates synchronization errors between separate control and interface modules.

- Improved signal integrity: On-chip integration reduces electrical noise and timing jitter.

In radiation-prone space environments, architectural simplicity and robustness directly translate into higher mission assurance. The PolarFire® FPGA SoC’s inherent radiation tolerance, coupled with this integrated design, helps lower overall mission risk while improving long-term operational stability.

3- Higher Performance with Real-Time FPGA Acceleration

At the heart of the Instrument Control Unit (ICU), the PolarFire FPGA SoC combines programmable logic and processing resources to deliver deterministic, real-time performance. The device brings together:

- Deterministic logic fabric: Supports high-speed sensor interfacing, implementation of custom control loops, and execution of real-time thermal algorithms.

- Hard or soft processor cores: Enable supervisory control, telemetry formatting, communication protocols such as SpaceWire, CAN, or UART, and continuous health monitoring.

- On-chip memory and flexible I/O: Reduce the need for external components while enabling tailored interfaces for a wide variety of payloads.

The outcome is a responsive and adaptable ICU architecture capable of running complex control strategies while sustaining high-throughput payload communications at the same time.

4- Simplified Integration and Reduced Lifecycle Cost with the ICU

By consolidating multiple functional roles within the Instrument Control Unit (ICU), spacecraft programs can significantly reduce integration complexity and verification effort. Integrated subsystems reduce the number of integration steps and validation cycles:

- Single qualification path instead of two: Lower overall test and certification cost.

- Unified firmware baseline: Fewer firmware images to maintain, validate, and update.

- Streamlined documentation: A single interface control document (ICD) supported by consolidated test reporting.

The overall result is faster integration, reduced programmatic risk, and a lower total cost of ownership across the mission lifecycle.

5- Flexibility and Scalability for Future Missions

The programmable nature of the Instrument Control Unit (ICU), enabled by the PolarFire FPGA SoC, allows the subsystem to adapt to evolving mission requirements without major hardware redesign. Thanks to this flexibility:

- Payload interfaces can be reconfigured for different communication protocols through firmware updates rather than physical modifications.

- Thermal control strategies can evolve after deployment, enabling adaptive and mission-specific temperature management.

- Modular logic resources support configurations across a wide spectrum of platforms, from small LEO satellites to complex deep space missions.

This scalability ensures that a single ICU architecture can serve multiple programs while remaining responsive to future operational demands.

6- Radiation Tolerance in the Instrument Control Unit

Spaceborne electronics must survive and operate reliably in the presence of ionizing radiation and single-event effects. Within the Instrument Control Unit (ICU), the radiation-tolerant PolarFire FPGA SoC forms the foundation for resilient and predictable operation. The platform provides:

- SEU and SEL resistance through hardened logic and configuration memory.

- Built-in mitigation techniques, including ECC and TMR, implemented across hardware and firmware.

- Reliable telecommand and telemetry handling without excessive susceptibility to bit flips or latch-up conditions.

Together, these capabilities increase mission uptime and significantly reduce the probability of premature subsystem failure.

The Strategic Value of the Instrument Control Unit

By consolidating the Thermal Control Unit and the Payload Interface Unit into a unified Instrument Control Unit (ICU), spacecraft designers gain a tightly integrated subsystem engineered for modern mission demands. The ICU delivers measurable advantages across multiple dimensions:

- Reduced mass, power, and volume

- Enhanced system reliability

- Shorter integration and verification timelines

- Lower lifecycle and program costs

- High performance with in-flight reconfigurability

- Dependable operation in radiation-intensive environments

For spacecraft integrators, the ICU provides a streamlined and capable platform for managing payload interfaces and thermal regulation within a single architecture. This approach reduces subsystem complexity and allows engineering teams to focus their effort on mission-unique capabilities and performance differentiation.